-

Machine tools

-

Machine tool accessories

-

Welding, cutting equipment

-

OEM Machined parts, components

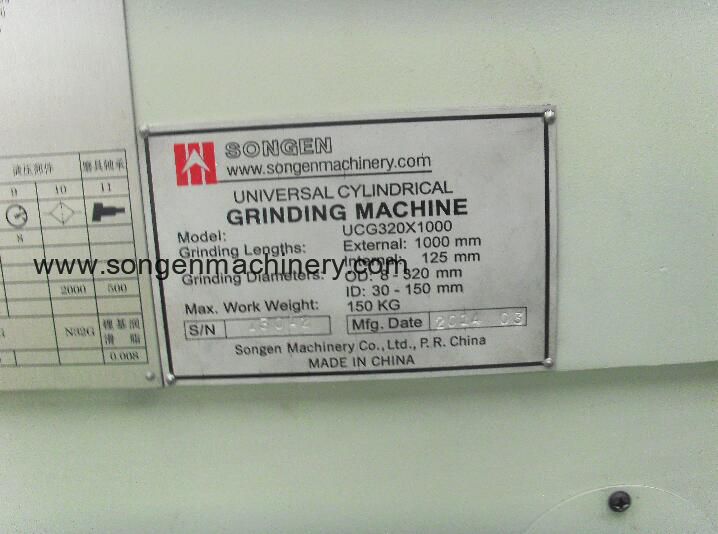

This model UCG320 external/internal unviersal cylindrical grinding machine features a simple and compact structure, T-shaped layout, and eacy operations. It is a general-purpose grinding machine used for grinding external/internal cylindrical/tapered surfaces on axisymmetrical workpieces. This model of external/internal universal cylindrical grinding machine is available with distances-between-centers as 1000mm, 1500mm, 2000mm, 3000mm, you can choose the right distance with the machine as per the workpieces to be ground. Due to its easy operations and efficiency on performance and productivity, this universal cylindrical grinding machine is widely used in the single-piece, samll-batch or mass production in workshops;

This universal cylindrical grinding machine consists mainly of the work head, the tailstock, the grinding wheel head, the internal grinding attachment, the worktable, the cross feeding mechanism, the hydraulic system, the cooling system, the lubrication system and the electrical system;

Heavy machine bed on this cylindrical grinding machine provides a rigid base to support all the units and features high stiffness and adequate length to support the worktable on all positions;

The work head is usually located at the left end of the worktable but can also be moved to any desired positions along the longitudinal direction on the worktable. It swivels on an infinitely adjustable scale from 0 degree to counter-clockwise 90 degrees to grind concial surfaces on the workpieces;

A variable-frequency motor is mounted on the work head to drive the spindle, thus the spindle speeds can be conveniently adjusted through operating the variable-frequency converter which drives the spindle motor. A tailstock mounted on the worktable holds the workpieces with the work head. It moves and locates on any position along the worktable;

The worktable longitudinal movements can be actuated steplessly at variable speeds by the hydraulic forces or be driven with hand wheel. It swivels anticlockwise up to 7 degrees and clockwise up to 3 degrees. It consists of the upper table and the lower table. On the guideways of the lower table, there are pressured lubrication cavities which receive lubrication oil to slightly float up the table and lubricates its guideways so that the friction on guideways can be eliminated;

The cross feeds of the grinding wheel head can be hydraulically driven to perform micro feeds and rapid traverses. It can also be manually driven with the hand wheel to perform coarse feeds and fine feeds.

Grinding performance accuracy:

External grinding roundness: ≤0.0025 mm

External grinding cylindricity: ≤0.008 mm

Internal grinding roundness: ≤0.0025 mm

Internal grinding cylindricity: ≤0.01 mm

Grinding surface roughness: Ra≤0.2 μm

Standard accessories:

1. 3-Jaw self-centering chuck, OD 200mm, c/w revisible jaws;

2. Open-type steady rest;

3. Carbide tipped center, MT #4;

4. Internal grinding attachment, 10000 RPM speed;

5. External grinding wheel, OD400 x Width50 x ID203;

6. Internal grinding wheel, OD35 x Width25 x ID10;

7. Grinding wheel pressing plate;

8. Grinding wheel periphery dresser;

9. Grinding wheel balancing mandrel;

10. Grinding wheel detaching wrench;

11. Measuring bridge plate;

12. Machine leveling pads;

13. Driving rod and lathe dog;

14. Coolant system.

Optional accessories:

1. Grinding wheel balancing stand;

2. Magnetic separator;

3. Center grinding attachment;

4. Close-type steady rest;

5. End wheel dresser;

6. Radius wheel dresser.

| Specifications | Unit | Models | |||

| UCG320X1000 | UCG320X1500 | UCG320X2000 | UCG320X3000 | ||

| GENERAL CAPACITY | |||||

| Distance between centers | mm | 1000 | 1500 | 2000 | 3000 |

| Center height | mm | 180 | 180 | 180 | 180 |

| Diameter ground (OD) | mm | 8 - 320 | 8 - 320 | 8 - 320 | 8 - 320 |

| Diameter ground (ID) | mm | 30 - 100 | 30 - 100 | 30 - 100 | 30 - 100 |

| Maximum length ground (OD) | mm | 1000 | 1500 | 2000 | 3000 |

| Maximum length ground (ID) | mm | 125 | 125 | 125 | 125 |

| Maximum weight of workpiece | KG | 150 | 150 | 150 | 150 |

| WORK HEAD | |||||

| Swivel angle | Degrees | CCW 90 | CCW 90 | CCW 90 | CCW 90 |

| Center taper | MT | #4 | #4 | #4 | #4 |

| Spindle speed | RPM | 50Hz: 25 - 220 60Hz: 30 - 364 | 50Hz: 25 - 220 60Hz: 30 - 364 | 50Hz: 25 - 220 60Hz: 30 - 364 | 50Hz: 25 - 220 60Hz: 30 - 364 |

| GRINDING WHEEL HEAD | |||||

| Wheel spindle speed | RPM | 1670 | 1670 | 1670 | 1670 |

| Wheel rapid traverse travel | mm | 50 | 50 | 50 | 50 |

| Maximum travel of wheel | mm | 246 | 246 | 205 | 205 |

| Swivel angle | Degrees | ± 30 | ± 30 | +10 | +10 |

| Feed per handwheel revolution | mm | Rough: 2.0 Fine: 0.5 | Rough: 2.0 Fine: 0.5 | Rough: 2.0 Fine: 0.5 | Rough: 2.0 Fine: 0.5 |

| Feed per graduation on handwheel scale | mm | Rough: 0.01 Fine: 0.0025 | Rough: 0.01 Fine: 0.0025 | Rough: 0.01 Fine: 0.0025 | Rough: 0.01 Fine: 0.0025 |

| Max. grinding wheel (OD x Width x ID) | mm | 400 x 50 x 203 | 400 x 50 x 203 | 400 x 50 x 203 | 400 x 50 x 203 |

| INTERNAL GRINDING ATTACHMENT | |||||

| Spindle speed | RPM | 10000 | 10000 | 10000 | 10000 |

| Grinding wheel (OD x Width x ID) | mm | Max. 50 x 25 x 13 Min. 17 x 20 x 6 | Max. 50 x 25 x 13 Min. 17 x 20 x 6 | Max. 50 x 25 x 13 Min. 17 x 20 x 6 | Max. 50 x 25 x 13 Min. 17 x 20 x 6 |

| WORKTABLE | |||||

| Feed per hand wheel revolution | mm | 6 | 6 | 6 | 6 |

| Maximum swivel angle | Degrees | Clockwise: 3 Anti-clockwise: 7 | Clockwise: 3 Anti-clockwise: 6 | Clockwise: 2 Anti-clockwise: 5 | Clockwise: 2 Anti-clockwise: 3 |

| Longitudinal rapid traverse speed | mm/Minute | 10 - 4000 | 10 - 4000 | 10 - 4000 | 10 - 4000 |

| TAILSTOCK | |||||

| Center taper | MT | #4 | #4 | #4 | #4 |

| Quill travel | mm | 30 | 30 | 30 | 30 |

| MOTORS | |||||

| Grinding wheel head motor | KW | 5.5 | 5.5 | 5.5 | 5.5 |

| Internal grinding attachment motor | KW | 1.1 | 1.1 | 1.1 | 1.1 |

| Work head motor | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| MACHINE SIZES AND WEIGHTS | |||||

| Net weight | KG | 3700 | 4300 | 6600 | 7200 |

| Gross weight | KG | 4000 | 4600 | 6900 | 7500 |

| Packing size | mm | 3200 x 2000 x 2050 | 4200 x 2000 x 2050 | 5400 x 2000 x2 050 | 7390 x 2000 x 2050 |

Horizontal lathes

Horizontal lathes