-

Machine tools

-

Machine tool accessories

-

Welding cutting equipment

-

OEM Machined parts components

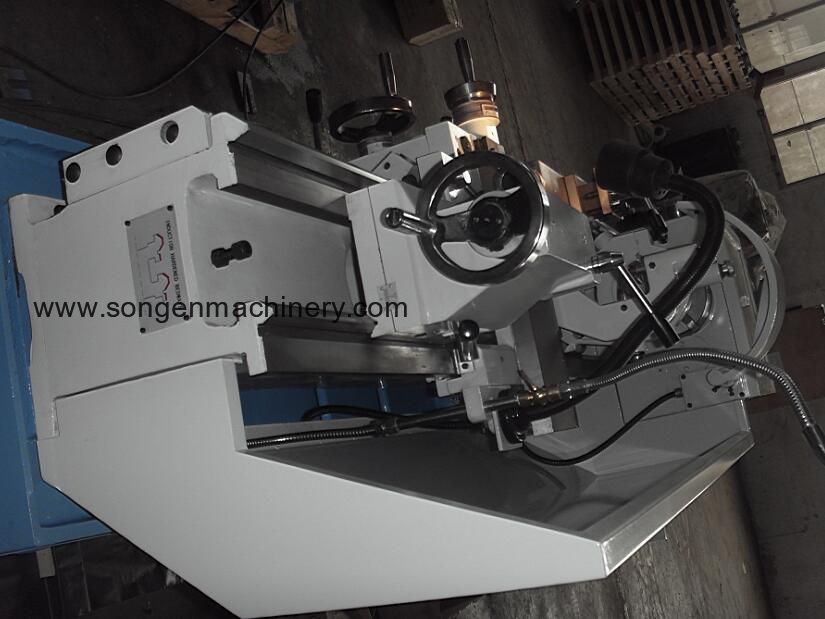

BLQ2360Kx1000 Horizontal engine lathe

- Geared head with high spindle speeds for precision turning;

- Hardened and precision ground gears are featured in the headstock and gearbox;

- Very rigid machine bed with heavy ribbing;

- Bed ways ultrasonic frequency quenching hardened and precision ground;

- D1-4 spindle is precision ground for accuracy and supported on high-precision tapered roller bearings;

- Headstock is constantly oiled during operation;

- Splined, not keyed, shafts are utilized in the headstock;

- Gearbox gives large threading and feed capabilities with no need for gear changes;

- Gap bed section provided for larger diameter workpiece;

- Independent lead screw and feed rod;

- Spindle actuation control is apron mounted;

- Automatic feed and threading are fully interlocked;

- Inch-metric thread chasing dials are supplied as standard accessories;

- Compound rest and cross slide have backlash elimination;

- Adjustable gibs are incorporated in the carriage and the bed ways;

- Tailstock may be offset for turning tapers and includes an inch-metric graduated quill;

- Tolerance test certificate included with machine in supply;

- Heavy-duty Stand;

- 150mm 3-jaw direct mount scroll self-centering chuck with two sets of jaws;

- 200mm 4-jaw independent chuck with reversible jaws;

- 250mm face plate;

- 40mm Diameter spindle bore, option as 51mm;

- Four-way tool post;

- Steady rest and follow rest

- Micro-carriage bed stop;

- Front removable chip tray;

- Spindle jog button;

- Pedal brake for quick start or stop of the machine decreases the standby time;

- Main power supply is shut off automatically when the electricity cabinet door is opened or the change gear box hood is opened;

- Coolant system with splash guard;

- Metric change gears;

- Halogen work lamp;

- Centers MT #3, MT#5 and headstock center adpating sleeve;

- Machine color decided by buyer.

Standard accessories:

1. 3-Jaw self-centering chuck (160mm) c/w reversible top jaws;

2. 4-Jaw chuck (200mm) with reversible top jaws;

3. Face plate (250mm);

4. Steady rest;

5. Follow rest;

6. Dead center MT #5;

7. Dead center MT #3;

8. Center adapting sleeve MT #5/#3;

9. Thread chasing dial;

10. Splash guard;

11. Halogen work lamp;

12. Stand & oil tray;

13. Toolbox & tools;

14. Coolant system;

15. Pedal brake

Optional accessories:

1. 2-Axis (or 3-Axis) digital readout system;

2. Quick change tool post, with one pc of tool holder;

3. Lead screw guard;

4. Chuck guard;

5. Live center MT #3;

6. 5C collet chuck with collets of sizes range decided by customer;

7. Taper turning attachment;

8. Other accessories on requests.

| Model | BLQ2360Kx1000 |

| Distance between centers | 1000 mm |

| Swing over bed | 360 mm |

| Swing over gap | 508 mm |

| Swing over cross slide | 210 mm |

| Bed width | 260 mm |

| Taper of spindle bore | MT #5 |

| Spindle nose | D1-4 |

| Spindle bore | 40 mm |

| Steps of spindle speeds | 12 |

| Range of spindle speeds | 40-1800 rpm |

| Range of cross feeds | 0.024-0.359 mm/rev. |

| Range of longitudinal feeds | 0.043-0.653 mm/rev. |

| Range of Inch threads | 4-56 T.P.I. /28 Kinds |

| Range of Metric threads | 0.4-7 mm /37 Kinds |

| Top slide travel | 92 mm |

| Cross slide travel | 180 mm |

| Tailstock quill travel | 120 mm |

| Taper of tailstock quill | MT #3 |

| Motor | 2.2 KW, 400V/3Ph/50Hz |

| Packing size | 1900x750x1510 mm |

| Net weight | 1150 KG |

| Gross weight | 1350 KG |

Horizontal lathes

Horizontal lathes