-

Machine tools

-

Machine tool accessories

-

Welding, cutting equipment

-

OEM Machined parts, components

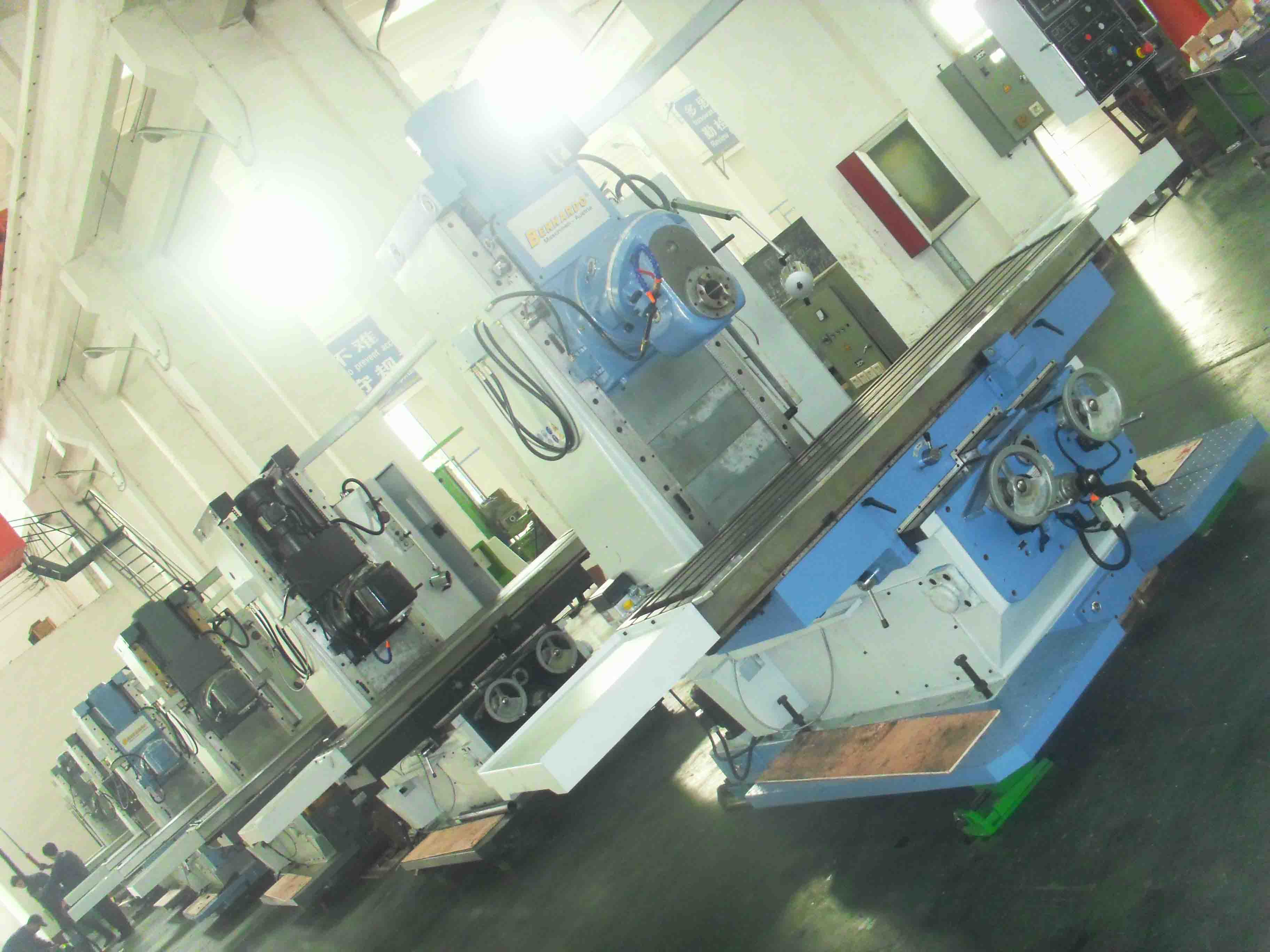

- Bed-type milling machine with large capacity for milling large parts and heavy machining. The extremely rigid large box-column, made of high-density and close-grained premium grey cast iron, provides a rigid machine base for performing stable and precision cutting even at very worktable loads;

- The large worktable 2100x500mm worktable on this bed-type milling machine travels only in the longitudinal direction (X-Axisi) and in the cross direction (Y-Axis). Combined with the powerful universal swivel milling head (fitted with 7.5 KW motor) which travels in the vertical direction (Z-Axis), the worktable allows the bed-type milling machine to carry a single large&heavy workpiece or multiple workpiece in a single set-up and take heavy cutting with high precision and stability even at very high table loads;

- The universal swivel milling head on this bed-type milling machine features high cutting power, maximum rigidity and performs quiet operations. The angle of its position can be set manually on a infinitely adjustable scale from 90º to 45º, therefore the milling head can be adjusted easily to any user-defined spatial angles or horizontal position. Benefitting from its high rigidity, this bed-type milling machine can take both vertical milling and horizontal milling with high stability, low vibration, increased machining precision and very high table loads;

- A horizontal cutter arbor supporter is provided with this bed-type milling machine. It has excellent rigidty, allowing the user to fully utilize the advantages of this bed-type milling machine for machining with long horizontal cutter arbors.

- Extra wide box guideways on X and Y axes ensure maximum rigidity and precision at high table loads;

- All gears, shafts and guideways on this milling machine have been high-frequency hardened and precision ground for lasting precision;

- Infinitely variable feed on all X, Y, Z axes;

- A 3-axis digital readout position indicator is assembled with the machine, ready for operation to ensure high operating accuracy;

- Control panel is mounted on an extending arm and can be positioned as per the ease of operator.

Standard accessories:

1) 3-Axis digital readout as position indicator;

2) Universal swivel milling head;

3) Cooling system;

4) Draw bar;

5) 1 Set of ISO 50 milling chucks (8 Pcs of collets Ø4,6,8,12,16,18,22,26mm);

6) Horizontal milling cutter arbor Ø40mm;

7) Horizontal milling cutter arbor Ø32mm;

8) Horizontal milling cutter arbor supporter;

9) 7:24 Taper sleeve ISO 50/MS 4;

10) Work lamp;

11) Operating tools;

12) Foundation bolts M12 x 500 mm;

13) Operation manual.

Optional accessories:

1) Milling chucks;

2) Machine vises;

3) Reduction sleeves;

4) Tailstocks for rotary tables;

5) Rotary tables;

6) Dividing heads;

7) Angle plates.

Horizontal lathes

Horizontal lathes